Tatami, originating from the wisdom of the Japanese people during the Heian period, is a combination of rice straw and rush-grass sewn together.

The unique sensation it provides and its charm have been appreciated for a millennium.

Rice straw tatami mats have many wonderful properties.

In our factory, we manufacture tatami mats from natural materials that respect your health and the environment.

Rediscover the traditional Japanese tatami made of rice straw.

Rice straw tatami mats

“Real rice straw tatami mat” is the brand manufactured in our factory and is an Eco Mark certified product, respectful of people and the environment.

Traditional tatami mats made by combining rice straw hard mattresses and rush-grass cover mats, all sewn together with thread, have been loved by the Japanese for over 1,000 years.

In modern society, tatami mats made from natural materials are a classic product that meets SDG initiatives regarding global environmental issues.

We offer real rice straw tatami mats recommended for construction sites using tatami mats nationwide.

Features

The raw material of the rice straw hard mattress is made of 100% rice straw from Miyagi Prefecture with a moisture content of less than 15%.

Despite the lack of raw materials, we do not use imported rice straw, as many other manufacturers do, nor do we use recycled rice straw obtained by dismantling old used tatami mats, due to pesticide residues.

We use self-made rice straw mats.

The mat is made by removing the leaves and braiding only the stems one by one as similar to a rush-grass cover mat.

By using rice stalk mats, made flat and without holes, inside the tatami hard mattress, it will remain flat for many years. Once woven, the mat is much more durable.

Our factory sells rice straw hard mats as flooring material to tatami stores across the country in 5 quality levels. Each quality level is determined based on the sorting of the raw material, the number of rice stalks inside and the spacing of the seams.

The leaves of the rice straw are removed

The leaves of the rice straw are removed

Rice straw stalk weaving machine

Rice straw stalk weaving machine

Insect repellent measures

Since it is a natural material, it can attract pests depending on the indoor environment and how it is used.

In our factory, we use tatami hot air drying equipment (external temperature of 100℃ and internal temperature of the mattress reaching 65℃) for 2 hours to exterminate pests from finished hard mattresses. Bacteria and parasites are killed after one hour at 50℃.

Additionally, before the tatami cover is laid, the hard mattress is wrapped in insect repellent paper containing borate as the main ingredient, providing a double measure of protection.

◎If you do not want insect repellent paper incorporated, please inform us in advance.

Rice straw tatami test results, June 18th, 2021 (survey conducted by Kitanihon Kankyo Co., Ltd.)

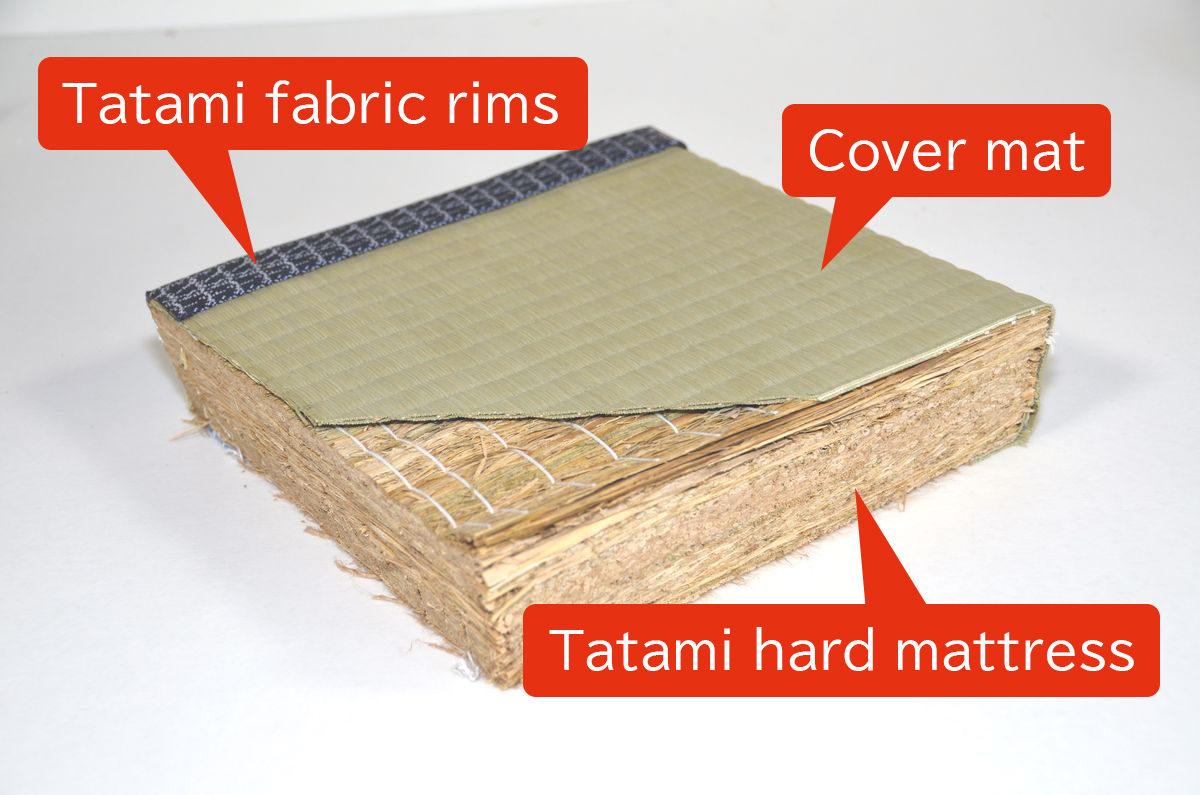

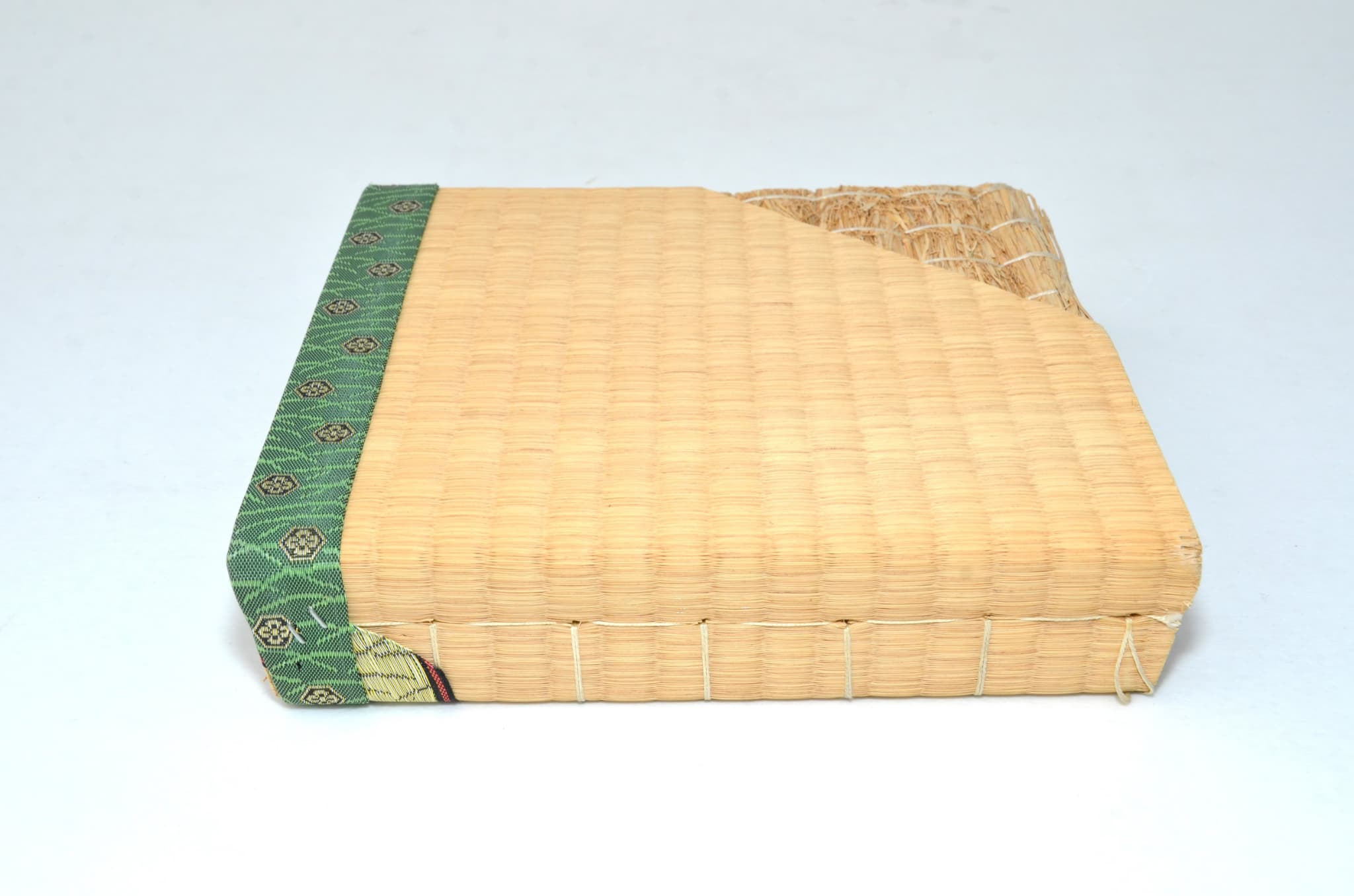

Tatami structure

The tatami is made up of three parts: the hard mattress (tatami doko), the covering mat (tatami omote) and the fabric rim (tatami beri). The hard mattress, which represents most of the thickness of the tatami, is the most important part, the one that determines the qualities of the tatami.

A tatami is made by stacking rice straw in layers of approximately 40 cm and sewing them together while compressing them to approximately 5 cm. Its strength creates a unique sensation that is neither too soft nor too hard. Its superior qualities are incomparable to other tatami mats. It is a blessing of nature to utilize the by-products of rice cultivation.

Rice straw hard mattress

Our quality standards

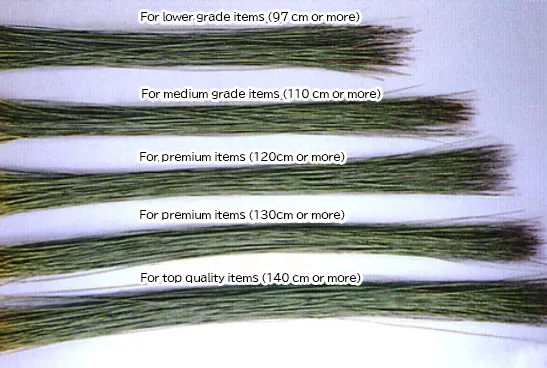

We produce products in 5 quality levels, from special grade quality to grade 3.

As a guide, the more expensive the product, the more layers of high quality rice straw, sewn together with attention to detail.

It is resistant, without irregularities and lasts a long time, even after many years of use.

Tatami hard mattress “rice straw sandwich” style

This hard mattress is made by sandwiching polystyrene foam between rice straw. This is an intermediate type of tatami that is lighter than real rice straw tatami and has a similar feel.

Often used in public buildings, there are three quality standards.

Hard mattress made of building materials

This hard mattress is made by combining wooden planks made from compressed fine wood and mixed with glue and polystyrene foam. It is lightweight, inexpensive and currently the most popular type of tatami. Since the raw material is wood, it is harder than rice straw. Additionally, the higher the foam rate, the less durable it will be. The most popular type is Type III, which has foam sandwiched between wooden planks, but there is also Type I, which only has wooden planks without foam, and Type II, which has two layers of foam above and below the board.

Ultra thin hard mattress

The demand for tatami mats for Japanese-style rooms ranging from 5 to 6 cm thick (the same thickness as flooring, 1.5 cm) has been increasing for around 20 years to accommodate “barrier-free” housing.

Due to the difference in level, thin tatami mats are often used as flooring. The thinner the tatami mat, the harder the material used must be to resist the traction of the tatami cover. If we attach the tatami as is, it will have the same feel as regular flooring, so we add cushioning material to the surface.

Covering surface (tatami omote)

The tatami cover is made by weaving rush-grass and thread.

There were once various “tatami omote” production areas across the country, but currently, about 97% of the nation’s covers are produced in Kumamoto Prefecture. Rush-grasses are classified based on their quality, length, color and number woven.

The rushes are sorted by quality, and the longest and best colored ones are used for high-end products.

There are two types of thread: cotton thread and linen thread. Linen thread is more durable than cotton thread. If the threads are strong, many rushes can be woven together, making the cover thick and durable.

In Kumamoto Prefecture, thanks to long-term improvement in species, there are four types of rushes, each with different characteristics.

Regardless of the variety, the quality of the rush is greatly influenced by the farmer’s growing techniques such as fertilizers and field management, and even the technique used to weave the grass you grew and harvested yourself can cause a big difference in the quality of the cover.

Kumamoto brand tatami cover mats (from the Kumamoto Prefectural Industrial Production and Sales Promotion Association website)

[Top quality cover mat]

“Hino Sarasa”

[High-quality cover mat]

“Hino Sakura”

[Premium quality cover mat]

“Sayaka Hino”

[Premium quality cover mat]

“Evening Calm”

[Premium quality cover mat]

“Haruka Hino”

[Premium quality cover mat]

“Cool Breeze”

How to distinguish cover mats (Kumamoto Prefectural Industrial Production and Sales Promotion Association website)

- Generally speaking, the longer the rush-grass, the higher the quality of the tatami cover. The tatami cover is woven using only the beautiful central part of the rush, excluding the roots and tips. This is why long rushes produce beautiful, high-quality tatami cover mats.

- Around 4,000 to 7,000 strands of rushes are used for each tatami cover mat. A good cover mat is one that has a large number of densely woven rush.

- Examine carefully the surface of the tatami cover mat and ensure that the elasticity is uniform, that there are no uneven colors, etc.

Collaboration: Yatsushiro Regional Agricultural Cooperative Association

Properties of tatami covers

- Air purification

It has the ability to absorb nitrogen dioxide, responsible for air pollution, and formaldehyde, responsible for sick building syndrome. - Heat retention/insulation properties

The cross section of the rush is spongy. It contains a lot of air and therefore maintains a suitable humidity level, like a duvet. Warm in winter and cool in summer. - Humidity adjustment

The tatami breathes. The spongy part of the rush absorbs moisture, and when the air is dry, it has the ability to release just the right amount of moisture.

This is another reason why it is the most suitable flooring material for Japan’s hot and humid climate. - Scent

The scent of tatami is a mixture of the “hay scent” that rushes naturally possess and the mud used in mud-dyeing, which has a natural aromatherapy effect and provides well-being.

Condition of the tatami cover after 6 years of use.

Tatami covers made of “igusa” (rush-grass) initially have the same green color, but the longer and better the grass, the more beautiful the color becomes with fewer black streaks.

[Inferior quality product from China]

Tatami cover for rental apartment

[Medium quality national product]

Tatami cover for common houses

[National luxury product]

Luxury brand Hino Sakura tatami cover

Difference between domestic and Chinese products.

Relatively inexpensive tatami cover mats made in China account for around 60% of the market. Because the rush is harvested about a month earlier while still immature, and because it is dried quickly at high temperatures, the surface of the rush is fragile and tends to fluff quickly. The natural strength and elasticity of the rush are lower than those of products made in Japan.

Tatami fabric rims

They are sewn along the entire length of the tatami to protect the corners of the tatami and for decoration.

Recently, rimless tatami mats have become popular.

In the past, natural cotton thread was used, but recently synthetic fibers, which are cheaper and more durable, have become mainstream. Cotton threads are often solid colors, and synthetic fibers have more than 1,000 types of products on the market, with a wide variety of patterns and colors.

The ambiance of the room changes depending on the tatami rim, so it is important to choose carefully.