Tatami from the Nara period

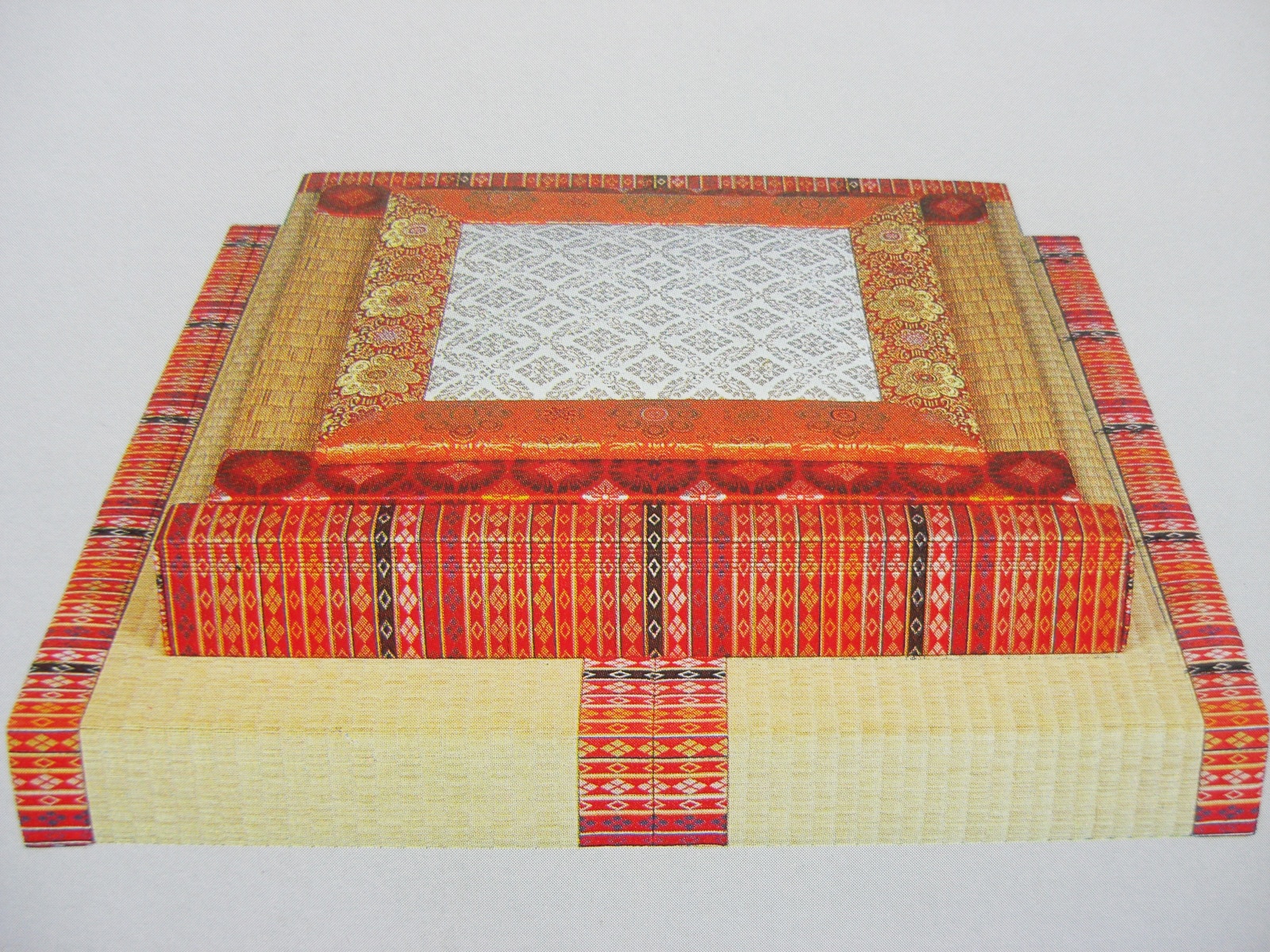

The first documented use of tatami is traced back to Gosho-no-tatami, used by Emperor Shomu (701-756 AD) in the Shoso-in treasure room of Todai-ji Temple in Nara. It was placed on a wooden platform and served as a bed. It was made by layering five or six pieces of a mat-like material woven from rice straw and a top covered with rush-grass and a hem of brocade to serve as the floor. It is considered to be the original form of tatami.

Origin of rice straw tatami

In the early 1000s, rice harvesting shifted from harvesting the cobs to harvesting the entire plant including roots, and rice straw became readily available as a byproduct. Because rice straw after threshing was easy to process, it was made into all kinds of daily necessities, such as ropes, waraji (traditional Japanese braided shoes), and mats.

Cutting the roots marks the start of rice straw culture. This is a typical rice straw tatami made with a combination of herbs. It is a true gift born from Japanese know-how.

Popularization of tatami mats

In the era of Shinden architectural style buildings (palatial architecture of the Heian era), the seat cushions and bedding were stored on tatamis placed on the storage boards. It is said that there were regulations regarding the thickness of tatami mats and the pattern of the hems, depending on the status of the user.

From carpet to floor covering

After the Kamakura period, when the architectural style became “Shoin-zukuri”, the entire room was covered with tatami, and tatami began to be used as a flooring material instead of just as a carpet. After the Muromachi period, with the development of the tea ceremony, the way tatami mats were laid changed and Sukiya-style buildings emerged.

Working Class System

Until this time, tatami mats were a symbol of power for aristocrats and samurai. Gradually it spread to samurai families and lower-class merchants. By the mid-Edo period, it expanded to common people living in apartment buildings, and a status-controlled six-class occupational system was established, including for example tatami sellers, craftsmen and, during the Genroku period, “tatami managers” (one of the job titles of the Edo shogunate. They managed the maintenance of tatami mats in the halls and various government offices of Edo Castle, and were responsible for the manufacturing and maintenance/replacement of tatami mats).

Popularization of tatami flooring

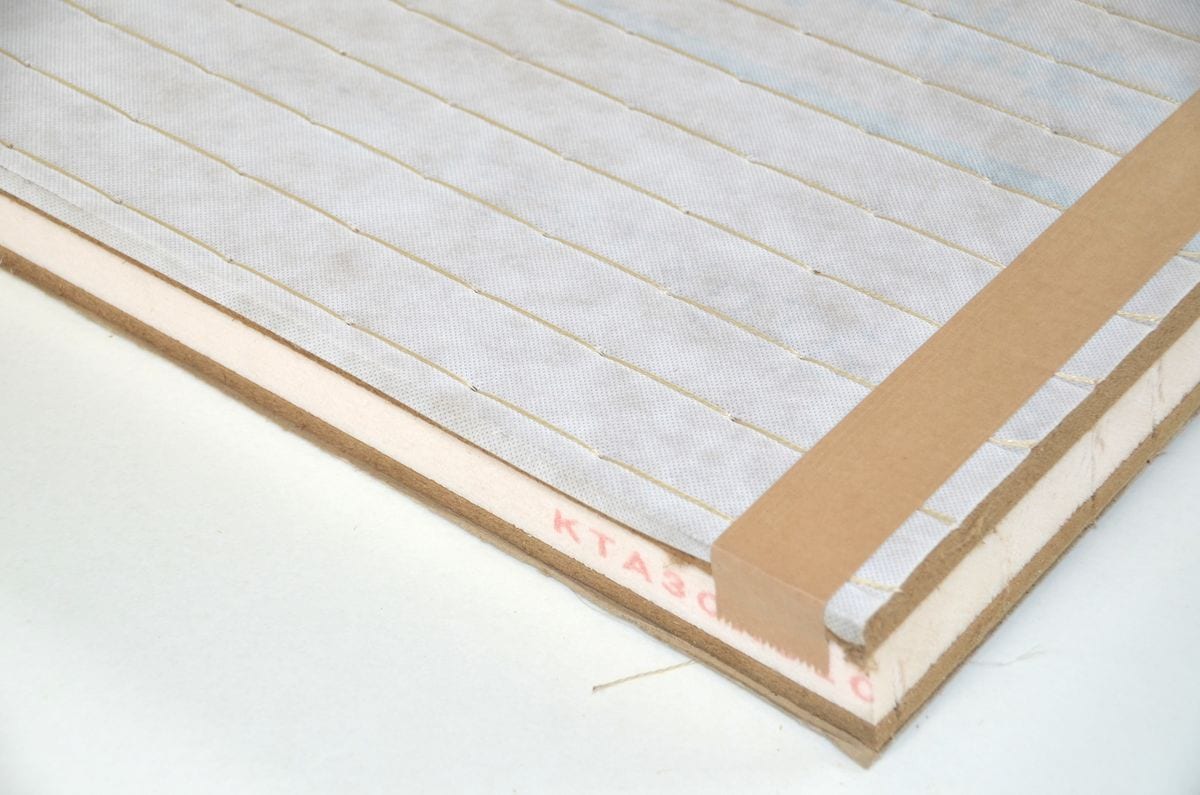

During the Meiji period, it spread to rural areas and 6 to 8 tatami rooms became common in ordinary homes, leading to the appearance of expressions such as “It’s better to have new tatami mats and new wives” as well as “I want to die on my tatami mat.” As the saying goes, before becoming a tatami craftsman you spend “3 years trampling the ground, 5 years making it”. The hard mattress of rice straw tatami mats are all made and sewn by hand, and the way the rice straw is arranged differs depending on the quality, and higher quality products are stacked vertically and horizontally in several layers and sewn with fine needles, which is still the case today. In the Taisho era, machines operated by hand appeared to make hard tatami mattresses. Until after the Pacific War (1941), during the Showa era, tatami shops carried out the entire process: purchasing rice straw from farmers, manufacturing hard tatami mats using hand-operated machines or hand sewing in their own factory, hand finishing the tatami top and hems, and delivering to customers.

The peak of demand for tatami mats

As housing construction expanded rapidly in major metropolitan areas during post-war reconstruction, tatami shops became so busy that they no longer had time to make hard tatami mattresses. Then began the division of labor between the production of hard mattresses, the finishing touches (cover and borders) and delivery to customers. Manufacturers of hard tatami mattresses were located in the suburbs where it was easy to collect rice straw, and there was a time when there were more than 500 manufacturers across the country.

Miyagi Prefecture has become Japan’s first major production area, with more than 100 companies mainly located around the Kanto region, providing more than 30% of total production. During the housing construction boom that reached its peak in 1971, rice straw tatami mats were imported from abroad.

Rice straw tatami hard mattress

Rice straw tatami hard mattress

Rice straw “sandwich” style tatami

Rice straw “sandwich” style tatami

Hard tatami mattress made of building material type Ⅲ

Hard tatami mattress made of building material type Ⅲ

Innovation in materials and manufacturing machines

Tatami mats, made by integrating expanded polystyrene foam into a “sandwich” between rice straw, have become popular to compensate for the lack of rice straw in Japan. A little later, wood-based hard fiberboard (insulating board) was developed.

Floor coverings combining polystyrene foam and building materials are approximately 40% lighter than rice straw tatami. Made lightweight and inexpensive, their market share has increased significantly. Around the same time, a fully automatic computer-controlled sewing machine was developed, making mass production possible, and a low-cost tatami mat was produced that combined a hard mattress made of lightweight construction materials with inexpensive rush-grass. Chinese-made rush-grass tatami mats still represents about 60% of the market. At its peak, more than 40 million tatami mats were made each year.

Computer controlled flat cutting machine

Tatamis: current situation

About 20 years ago, as homes became more accessible, the demand for thin tatami mats of around 15mm, the same thickness as parquet flooring, increased. Most tatami mats used as flooring are lightweight 15mm thick tatami mats which reduce unevenness and are easy to move and store. Currently, its market share barely reaches 20% and a new form of tatami living is emerging as the number of Japanese-style rooms diminishes.

When it comes to tatami surface, industrial tatami mats made from resin or Japanese paper come in a variety of designs and colors, and are now used in rooms equipped with “half-tatami” corners or as stand-alone tatami mats as much as common tatami mats are.

Igusa (rush-grass) tatami covers made from natural materials are in decline, including those made in China.

100% rice straw tatami mats, which were available until 50 years ago, have now become a rare item with a market share of less than 1%.

The modernization of agriculture and the expansion of the use of combine harvesters, which cut rice straw into smaller pieces, has caused the decrease of long rice straws that can be used to tatami mats and led to a shortage of raw materials. The fact that the materials and rice straws weigh more than 30 kg is the main factor in the gradual disinterest of tatami manufacturers and they stop using them due to their difficulty to handle.

Ultra-thin hard mattress with a final thickness of 15 mm

Tatami color variations

Threshing of naturally dried rice

Harvesting rice with a combine harvester

The craft techniques passed down from generation to generation are used in the production of rice straw tatami mats as in the past, today too and in the future. If this continues, the existence of real rice straw tatami will be threatened in the near future. We believe it is our mission to preserve straw tatami mats for the future, as they are part of this unique Japanese rice straw culture.