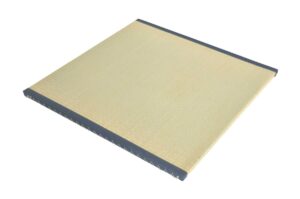

Waraku Tatami® is a traditional and authentic tatami made from a rice straw hard mattress at half the usual thickness, making it lightweight. It is to be placed on the floor and can be moved and stored easily.

Tatami mats made increasingly with artificial materials, are fixed with metal fittings such as staples and are attached to the floor with adhesive, so damaged tatami mats have to be thrown away. Our tatami mats use a thread stitching method and straw tatami mats can be repaired with the skills of a tatami craftsman. This involves replacing only the damaged cover mat while leaving the tatami hard inner mattress intact. It is economical because you can use quality products for a long time. Rice straw used as material is also a plant harvested from rice fields every year and is a typical product that contributes to SDG activities and addresses global environmental issues.

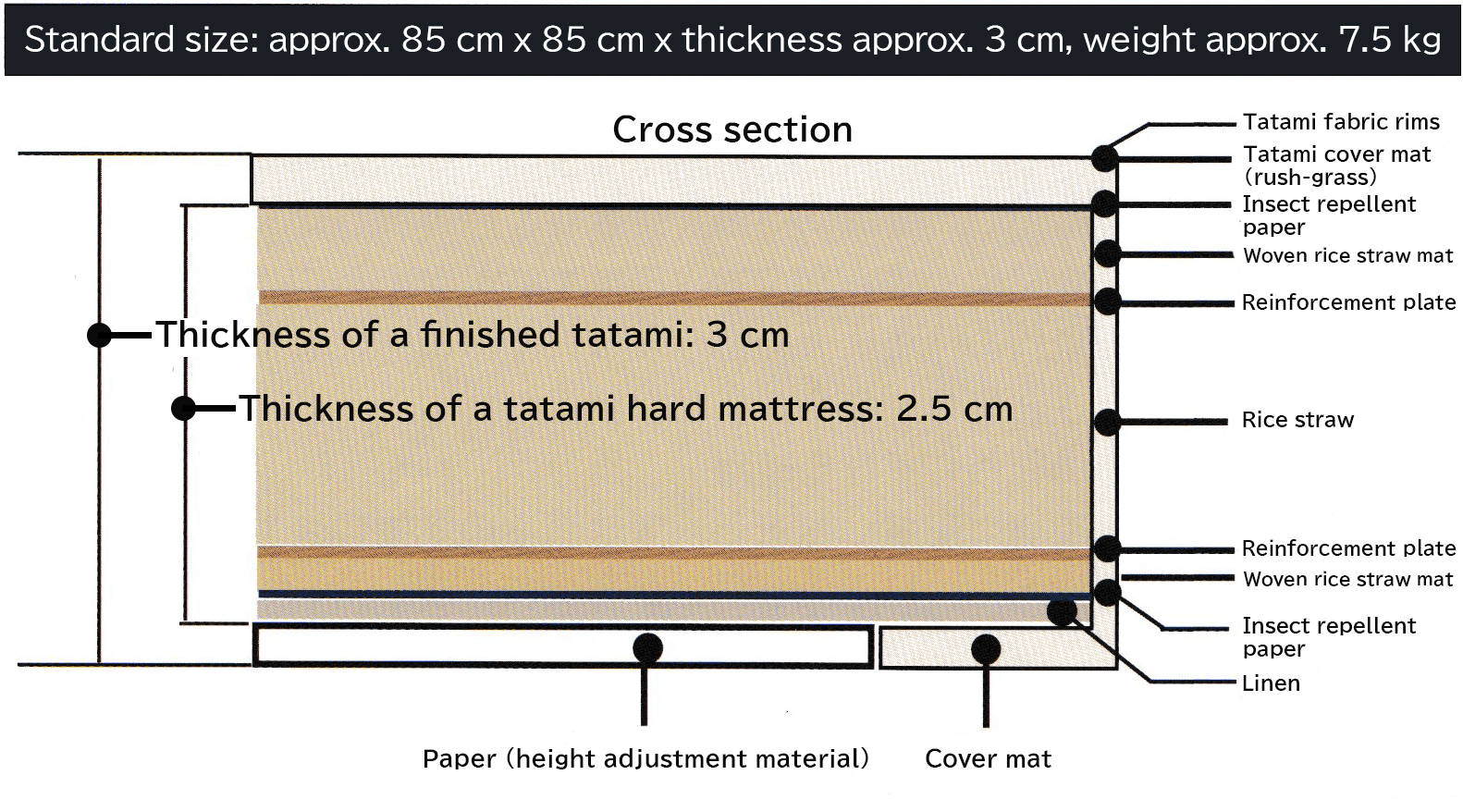

Specifications

How “Tatami Waraku®” is made

Waraku tatami hard mattress manufacturing process

1. Rice harvest scene

The raw material is 100% naturally dried, pesticide-free rice straw grown on JAS certified organic farmland Farmin Co., Ltd., an organic farm in Tome City, Miyagi Prefecture.

2. Threshing work / natural drying

The harvested rice is left to dry naturally for about a month, then it is threshed to separate it from the rice straw.

3. Bundling work

Grouping of rice straw (24 bales) to facilitate loading onto the truck.

4.Transport/Storage (warehouse)

Around 200 bales of rice straw (1 large bale containing 24 small bales weighs 6 to 7 kg) are loaded onto a truck, transported from the rice field to a warehouse for storage.

5. Manufacturing the rice straw mats

A characteristic of the Waraku tatami hard mattress is that it contains several woven rice straw mats, which are made by only meshing the stems of the rice straw (the part remaining after the leaves have been removed) one by one. Although it is thin and flat, it has the same durability as a thick tatami mat.

6. Hard mattress material layering process.

Every step of the Waraku tatami hard mattress manufacturing process is done by hand. Expert craftsman are required to arrange the rice straw evenly.

7. Finished hard mattress

To finish the hard mattress, a well-balanced layer of rice straw, a rice straw mat and a reinforcement plate (all together 20 cm thick) are sewn and flattened to 2.5 cm thick using a manufacturing machine developed by us.

Waraku tatami finishing process

8. Hard mattress cutting work

A fully automatic machine cuts the hard mattress, lengthwise, to the specified size.

9. Stile stitching work

The hard mattress is wrapped in a cover mat, stretched to avoid creases, and everything is sewn together with thread.

10. Flat stitching work

While cutting the hard mattress and the cover mat to the specified dimensions in the width direction, the tatami fabric rims are sewn together at the same time.

11. Tatami corner making and backstitching work

After flat stitching, the fabric border rim of the tatami is carefully folded by hand to create the corners which are very important. Everything goes through an automatic backstitch machine to sew the tatami edge.

12.In-process inspection

During the manufacturing process, we perform inspections to ensure dimensions are as ordered and that there are no scratches or discolorations on each mat. In the final finishing step, a food-based herbal anti-mold and anti-virus agent is applied to the tatami surface, and this concludes the finishing process.

13. Final inspection

Finally, we lay out all the tatami mats ordered, assemble the wooden frame if it is a set, and do a final inspection.

We pack and ship the ordered product in a manner to avoid damage. Regarding the level difference between the tatami and the wooden frame: there may be a slight level difference due to the dimensional errors of the wooden frame and the thickness error of the hard mat of the tatami which is handmade from natural materials. Please note that the allowable margin is set at 2mm or less.

Properties

Excellent insulation

Pleasant feeling to the touch

Historically recognized durability

+

Respect the environment

- Compared with wood panels and polystyrene, which are commonly used as insulation materials, it has 5.3 times better insulation performance at the same thickness.

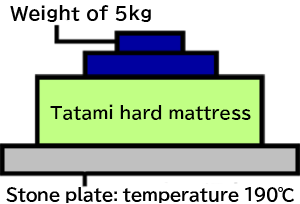

Experiment

Dimensions of the stone pannel: 210c m x 210 cm x 10 cm

To increase grip, a 5 kg steel weight is placed on top.

We placed a tatami mat at room temperature (31℃) on a stone plate heated to 190℃ and measured the time required for the tatami temperature to increase by 10℃.![]()

Result

The real tatami took 14 minutes 10 seconds, and the building material tatami took 2 minutes 39 seconds.

This hard mattress of real natural tatami has approximately 5.3 times more insulation performance than that of other building materials.Information provided by: Miyagi Prefectural Tatami Manufacturers Association

It has the unique elasticity and feel of tatami, neither too soft nor too hard.

It’s a warm rug made from natural materials.![]()

- One of 112 rice straw tatami mats dating from 1673 still used in a temple in Kyoto. Its long history proves its durability.

![]()

- Using our uniquely developed manufacturing machine, we create tatami hard mattresses with a thickness of 2.5 cm, which is half of the conventional thickness. It is the lightest rice straw tatami.

![]()

- The raw material is 100% pesticide-free rice straw that has been naturally dried to achieve a moisture content of 15% or less.

![]()

- Since the raw materials are natural materials produced every year, it is a Japanese Eco Mark certified product which is friendly to the environment and people.

![]()

- Damaged tatami covers and border rims can be replaced or repaired while keeping the hard inner mattress as is.

It is economical because you can use quality products for a long time.![]()

Differences with regular tatami mats

Many thin lay-on tatami mats using artificial materials, increasingly popular nowadays, are made by gluing the cover mat to the hard mattress with chemical adhesives, or attaching them with metal fittings such as staples. If the surface of the tatami becomes dirty or damaged they can only be discarded. The traditional method of thread stitching allows repairs to be made by replacing the tatami surface cover and rims while leaving the hard inner mattress intact. It can be used for a long time and is therefore economical.

Most thin tatami mats made from artificial materials have a sponge-like cushion layer of about 2 mm on the surface of the hard mattress, covering a very hard base. The feel is different from rice straw tatami mats, made by compressing straw.

Waraku Tatami® is based on natural materials, a combination of a rice straw hard mattress and a rush-grass cover mat from Kumamoto Prefecture, which go well together. The warmth and softness of natural materials will bring you well-being.

As for the border rims of the tatami mats, customers can choose their favorite one from the samples.

Waraku Tatami® is the newest modern times product, made using an ancient traditional method.

Difference between rimmed tatami mats and rimless ones.

It is said that during the Heian period, when tatami mats were first created, tatami used as mats had border rims on all sides, and the patterns were determined by the status of nobles and samurai.

In the Edo period, when tatami mats became more popular among the people, expensive tatami mats were used by big merchant houses, samurai and other high-status classes, and ordinary people began to use rimless tatami mats.

In modern times, rimmed tatami mats have become less expensive and thanks to automated computer-controlled production machines, they have become mainstream.

Rimless tatami mats, on the other hand, cannot be made using modern automated manufacturing machines; they require many manual processes, making them more expensive than rimmed tatami mats. Recently, we see the appearance of machines that can directly apply adhesive to the entire surface of flat tatami mats made of building materials. This makes it relatively easy to make rimless tatami mats, and makes them more affordable due to reduced costs.

The production of rimless tatami using a rice straw hard mattress is carried out by a tatami technician. The best know-how is necessary.

The production of rimless tatami using a rice straw hard mattress is carried out by a tatami technician. The best know-how is necessary.Insect repellent measures.

As it is a natural material, it is possible that insects may still be present inside.

In our factory, we use two methods to exterminate insects: we dry the hard mattress with hot air and lay out insect repellent paper, containing borate as the main ingredient, on the bottom and surface of the hard mattress.

Example of construction site

September 2020: we made Waraku tatami hard mattresses in our factory, and Kato Tatami store finished and installed them.

〇Nerima district in Tokyo, Kato Tatami store, house serving as an office (Builder: Kato Tatami store)

Tatami Waraku: 8 pieces (one tatami) with rims, 12 pieces rimless (half tatami)

© Mr. Masami Takahashi/City Environmental Architectural Design

〇Mr. Teraoka’s House, Karuizawa Town, Nagano Prefecture

Business name: Naikan Soan

Construction date: 2022

Main use: residence

Secondary use: meditation room

This room is used to turn inward and meditate throughout the day. “Naïkan”: this is a room for introspection, similar to zazen. That’s why there are no decorations.

Some people feel like they achieve great depth of mind when meditating in this room.

〇Customer reviews

Thank you for this wonderful tatami.

Thanks to you, I’m enjoying a good time.

It is a product which is a compendium of materials, thoughts, resistance, tradition and know-how.

Good quality products that resonate deeply in people’s hearts.

In my daily life, every time I see a tatami (Waraku) and feel it under my feet, I feel enriched.

I feel peaceful.

When I lie down, I feel a sense of calm.

Waraku tatami mats seem to be like companions living on earth with us.

I perceive them as “living beings”.

This is a photo of a refined simple room.

Place the tatami in a Western-style room. That’s all!